GlassWalk™ Structural Glass Floor Systems

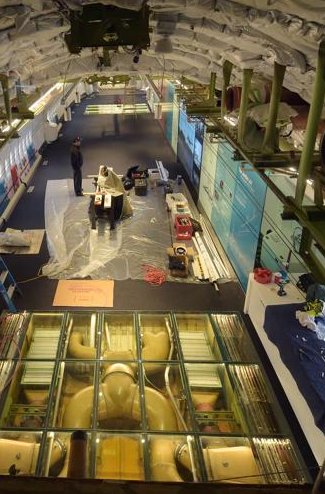

With over 25 years of proven performance in glass flooring, GlassWalk™ Structural Glass Floor Systems can’t be beat. A glass floor can help to open up any area while creating an eye-catching addition to your interior or exterior space. Structural glass is the perfect application to allow light to pass to areas beneath and likewise illuminate your outdoor spaces during the evening.

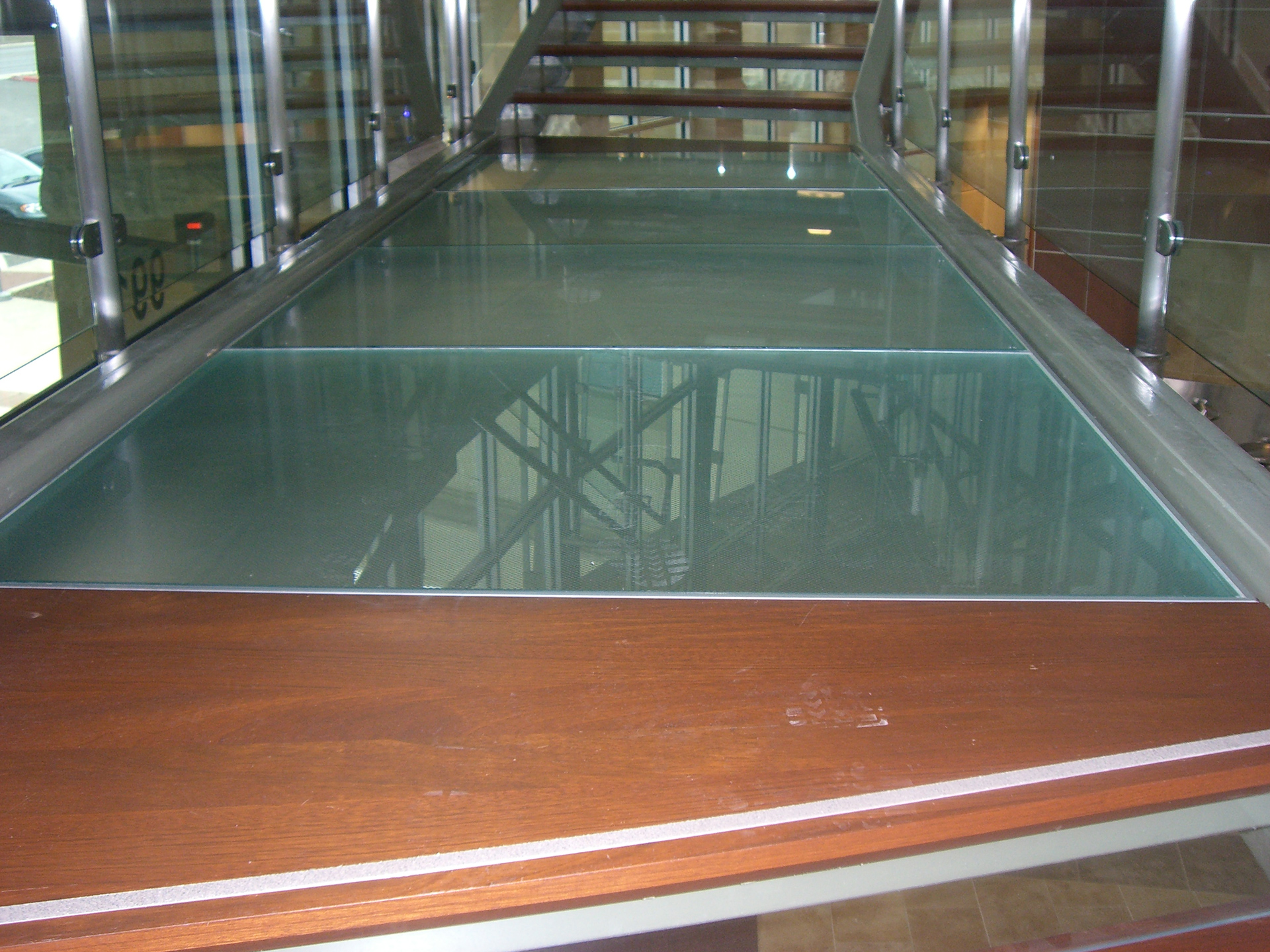

The GlassWalk™ Structural Glass Floor System includes 1″ fully tempered, laminated structural glass units. Typically an anti-slip, traction control frit pattern can be added to the top surface of the glass unit. Traction control, ceramic-based frits are permanently heat-fused to the walking surface of the glass to achieve slip resistance. Acid etch anti-slip surface process is also available. Both surface treatments meet or exceed the most stringent code requirements.

The heart of the glass floor system is a modular aluminum grid. Our aluminum grid is strong, lightweight, easy to install, and proven in hundreds of applications. Grids contain over 25% post-consumer recycled content, making them compatible with popular green-build standards.The glass and aluminum can also be engineered in custom shapes and sizes.

Glass floor panels are 2- or 3-ply laminated glass units, with a layer of fully tempered glass for added impact resistance. These glass units combined with the performance of the aluminum grid have been tested in independent labs to meet code requirements for load and impact. Glass floor panels are offered in standard glass or low iron, with a variety of translucent and transparent options available as well. GlassWalk Structural Glass system holds individual glass units up to 48 inches wide, set in a sturdy aluminum grid that comes as a kit, pre-manufactured to your exact specification.

For more information or design assistance with a custom shape, contact a GBA design expert today.

Structural Glass Floor Design Features

- Standard glass (greenish/blue hue) or low-iron glass

- Both standard and low-iron glass is available in 2 or 3-ply laminated glass units

- Customize the translucency or transparency of the glass

- Traction control frit patterns can be added to the top surface of the glass to aid in slip resistance

- Add color to the interlayer of the glass to add a unique splash of color to any structural glass floor system

- Structural glass can be custom cut in any shape or size to match the projects’ design

Architectural Grade Aluminum Grid

- Constructed of 6063-T6 aluminum making the framing both lightweight and stong

- Available in clear anodized, matte silver finish

- Aluminum framework can be powder coated to match any design

- Custom shapes and sizes can be created as intended by the design

- 25% post-consumer recycled content in aluminum structural members

Glass Flooring Installation

Like all GlassWalk systems, each structural glass installation is shipped as a complete kit, with all elements pre-cut to your exact specification – including the glass units themselves. GlassWalk floor systems utilize a patented aluminum grid, whose standard clear anodized finish offers an attractive view from any angle. Custom colors are also available.

Glass floor systems can be easy to install as long as you follow all instructions and carefully read construction details as well as provided shop drawings. It is vital to have approved shop drawings at the time of installation to verify the required opening size and glass floor dimensions are correct. Examine all components to ensure the glass did not break, chip, or scratch during shipping. Once all components have been examined and the opening dimensions has been verified, you are ready to start installing your glass floor.

Assemble the glass floor system according to the instructions provided by manufacturer into the opening. The top surface of the glass should lay flush with the adjoining floor surface, unless otherwise specified in the drawings. Apply sealant around each of the glass units and between the grid. Once all pieces have been installed and sealed with the requirements per the specifications, clean the exposed top surface.

Structural Glass Floor System Applications:

•Glass Floor Balcony

•Display Floors

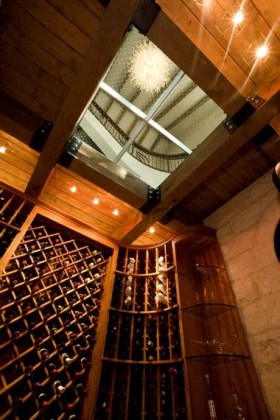

•Wine Cellars

•Pedestrian Bridges

•Residential Glass Floor

•Stair Landings

Architects: For a CE unit in any of 6 different programs, take our free online class: Glass Floor Walkways and Stair Treads.

![BIGglassfloor[1] internal-walk-on-glass-floor](https://glasswalkfloors.com/wp-content/uploads/BIG20glass20floor1.jpg)